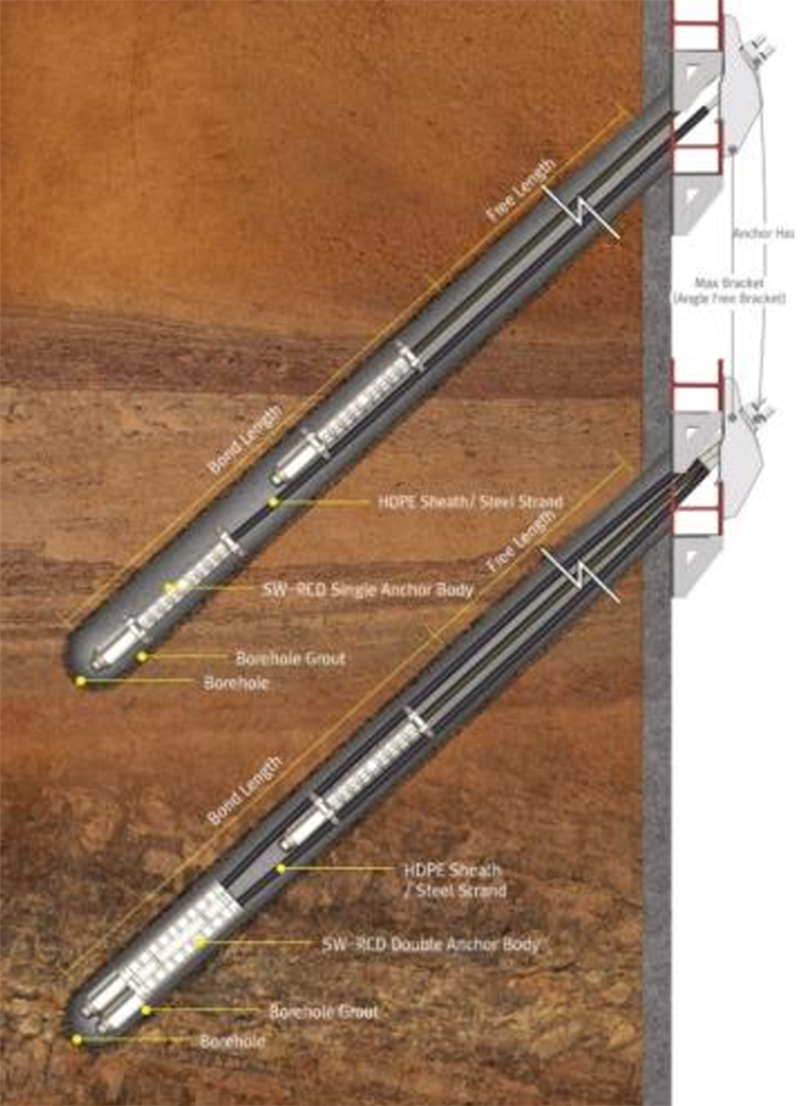

The SAMWOO - SW-RCD anchor is a load distributive compression type removable anchor that offers a complete solution where anchorage systems required to be removed once they become redundant. Often city municipalities and the like, object to obstructions left in the ground beyond completion of construction for fear they will conflict with future developments or seek third party approval. The SW-RCD anchors are a cost effective solutions where the use of conventional tieback anchors are forbidden or discarded due to logistical and or practical site constraints. The entire steel strand can be quickly and easily removed or reengaged with limited site access. Simply rotate the strand to release the wedges which are fixed in the end of the anchor body and the entire steel strand is easily withdrawn through the PE sheath leaving the small aluminium anchor body.

The removal process is generally done by hand. In addition, allowing the steel strand to penetrate through the inside and be secured to the end of the anchor body, distributes the jacking force along the length of the anchor body which maximizes the effective cross-sectional area of the grout body. Since their initial development these anchors have been employed in numerous projects around the world providing lateral support to temporary sheeting and shoring conditions.

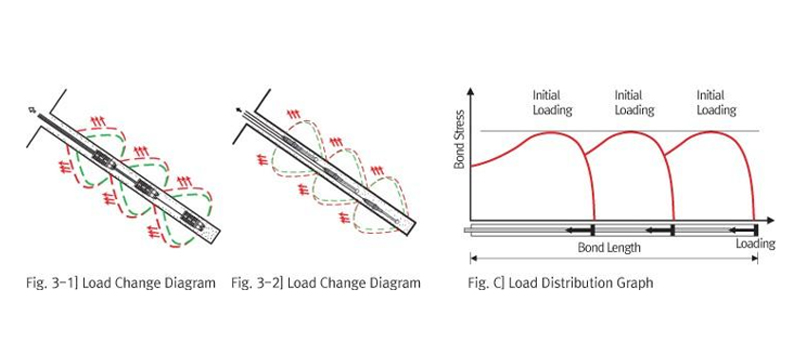

Compression type anchors consist of an unbonded polyethylene (PE)-coated steel strand which transfers the jacking force / load directly to a structural element located at the distal end of the anchor. Unlike the tension type anchors, the grout body for compression type anchors is loaded in compression which is capable of securing much higher loads. However, due to the concentrative design of these anchors, the use of high-strength grout is frequently required to secure the jacking forces at the distal end. Also, it is often difficult to secure concentrative anchorage force in weak soils. Similar to the tension type anchors, compression type anchors are subject to the occurrence of progressive debonding and time- dependent load reduction (creep) as displayed in state Ⓒ as shown in (Fig. B). In this case the friction required to secure the concentrated load exceeds that of the skin friction for that zone. This effect causes grout debonding and loss of soil confinement pressure resulting in load reduction as displayed in states ©and©.

As discussed, high stresses from tension and conventional compression type anchors transfer concentrated loads to the soil and grout body which can become overstressed resulting in failure. Therefore, load distributive compression type anchors have been developed and are being used, which uniformly distribute the anchor load to the grout body and soil along the theoretical length of the bond zone. In addition the grout strength requirements are reduced as well as applied eccentricity. As a result high loads can be achieved even in normal soil condition. Recently, load distributive tension type anchors have been developed which are capable of securing stable loads in even relatively weak soils such as clay and silts. These anchors do not require high strength grout and have low eccentricity as well. The use of load distributive anchors results in a more uniform distribution of the anchor force to the soil as illustrated in figure C below. Therefore, load reduction and creep are minimized, enabling the anchor to maintain initial design load.

We design and construct both permanent and temporary anchors using multi-strand in accordance with internationally recognised codes that have been adopted in India which include; British Standard Code of practice for Ground Anchorages BS 8081:1989, Execution of special geotechnical work – Ground Anchors BS EN 1537:2000, FIP Design and construction of prestressed ground anchorages April 1996 and US Federal Highway Administration Geotechnical Engineering Circular No. 4 Ground Anchors and Anchored Systems June 1999.

We have an extensive database of ground anchor testing and geotechnical ultimate bond ruptures in a wide range of materials nationwide. However, in any ground anchoring project, site specific geotechnical investigations for the construction of the ground anchors are critical to minimise the risk profile for all parties. Access to this information means we are better able to qualify potential drilling difficulties and any potential for loss of grout from the drill hole during the anchor installation.

For multi-strand anchors, the strands are run through our specialist greasing and sheathing machine. This machine parts the individual wires of the strands followed by immersion into a grease bath before completely encapsulating the strand in the outer sheathing to ensure no voids are present.

We utilise the technique of high-pressure (1000psi) post-grouting in weak compressible soils to significantly improve the bond capacity, and where required, fabric socks are used to ensure containment of grout within the drill hole thus ensuring full bond potential is realised.

Applications

- Underground Metro Projects

- Shore piling Support

- Ideal for Instable Soils such as Clay

- Single bore-hole load distributive anchor

- Uplift Raft Anchors

Capability

- Diameter from 125 mm – 300 mm

- Depths up to 35mm in headroom of 3mm

- Maximum design load of 330 Tons

- Constructed if necessary with a permanent linear through rock voids

Anchors

- Strand anchor with Anchor Body

- Capacity as per ground conditions

- Double corrosion protection

- Serviceable strand replacement anchors